Speaker Baffel 2006/07/08

click on each picture to zoom in

I built a baffel/soffet around my speaker. It's 48' tall by 56" wide by 3/4" thick. It's flush with the front of the speaker.

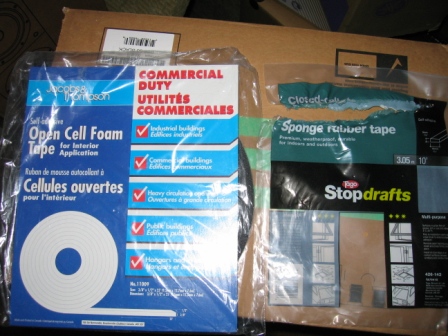

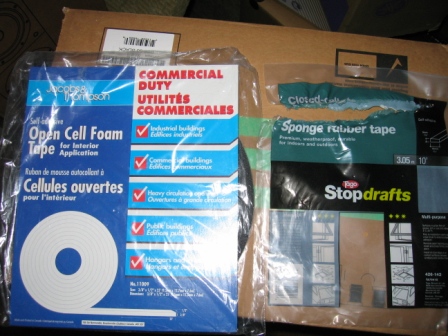

I was at home depot, and in the Stop Drafts section I found these two. The one on the right is closed cell sponge rubber tape 3/4" wide by 1/4" thick, and I stuck it onto the plywood to go around the speaker, and on the bottom of the plywood between the plywood and the floor (notice how I ran out on the left hand side). I made the hole for the speaker about 1/4" larger from side to side, and it was so tight that I had to put the baffle into place with a rubber mallot. Home depot had several that were open cell foam, so I bought one. Eric is frequently mentioning putting felt around the outside of doors between the 1.5" part of the door and the jamb -- I wonder if this open cell foam would work well there instead of felt.

Then I used some paper towels to draw a template with a pencil for the speaker drivers/cones, and placed that onto a 2'x4'x2" sheet of rigid rockwool, and cut out the holes.

And attached it to the front of the plywood.

If I do this for real one day (rather than just for testing) I'll do two things differently:

1) I'll cut out the lower woofer hole

2) I'll cone-cut the holes, especially the tweater, to 30 degrees rather than the 0 degrees they are now.

I wonder if 1" linacoustic (or 1/2") would have been better than the 2" of rockwool. I've read about people using linacoustic, but I'm the only person I know of who's put 2" of rockwool in front of the speaker.

According to bert stoltenborg:, who's pretty good with speaker technology especially line arrays:

a) If you put an absorber on a speakerfront you'll loose, frequency dependent, some output (dB).

So you modify the speaker response.

b) An absorbing hole in front of the tweeter will work as a horn, as the grazing waves will not be absorbed, so another freq dependent modification.

c) and the mid frequencies are a couple of dB down.